Projects Juan Palacios

Here we show some of the projects we have developped at Juan Palacios.

INTEGRAL AUTOMATION IN JUICE PRODUCTION

Automation of the storage, mixing, CIP cleaning and packaging process in a juice manufacturing factory. It includes the electrical engineering and its execution. Siemens PLCs, inverters and HMIs were used, as well as the Scada WinCC from the same manufacturer.

IMPLEMENTATION OF MES IN INDUSTRIAL MILLING WITH AVEVA AND SAP

Implementation of MES platform in industrial milling process through the use of AVEVA MES Performance software and its Model Driven libraries. The technological solution is also composed of the AVEVA System Platform visualization and operation system, AVEVA and Historian real-time database, and also carrying out communication exchange with SAP.

CHOCOLATE MILLING AND STORAGE AUTOMATION

Automation of the grinding, transport and storage process of chocolate powder in a chocolate manufacturing factory. It includes the electrical engineering and its execution in Atex 22 environment. Siemens PLCs and HMIs as well as Schneider drives were used.

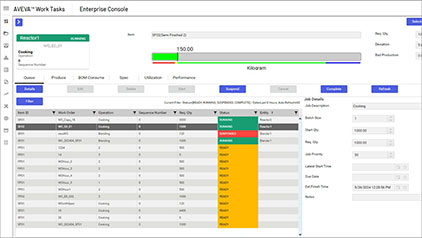

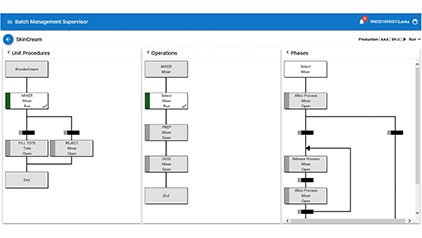

IMPLEMENTATION OF MES FOR BATCH AND RECIPE MANAGEMENT

Implementation of the MES system platform for batch and recipe management using AVEVA Batch Management for the sauce manufacturing process. The technological solution is also composed of the AVEVA System Platform visualisation and operation system, AVEVA and Historian real-time database, and also carrying out communication exchange with SAP.

AUTOMATION OF PARAFFIN STORAGE AND DOSAGE

Automation of the paraffin storage and preparation process in reactors by dosing of major and minor components in a perfume manufacturing factory. It includes the electrical engineering and its execution in Atex 2 environment. Siemens PLCs, Variators and HMIs were used.

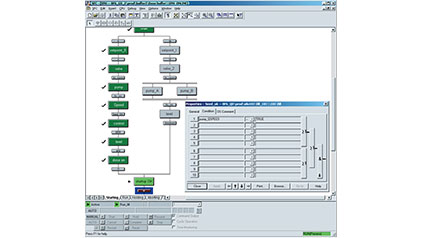

DOUGH COOKING AUTOMATION

Automation of dough cooking process using Siemens PLCs, Variators and HMIs through the distributed control system of the same manufacturer PCS7, for a confectionery manufacturing factory. Includes electrical engineering and execution.

TRACEABILITY MANAGEMENT IN DRUG MANUFACTURING

Implementation of a traceability management system using OPC Router and KepServer in a manufacturing process for a manufacturer of household products. The system interconnects a number of different types of equipment (PLCs, MES, ERP, BBDD, ….), manipulating and transferring the information according to a logic.

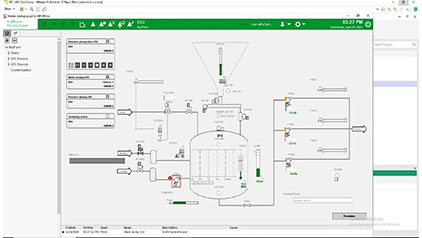

CEMENT MANUFACTURING AUTOMATION

Automation of the cement manufacturing process (grinding, conveying, additives, etc.) using Schneider PLCs, drives, and HMIs through the same manufacturer’s distributed control system, EcoStruxure Process Expert (EPE) for AVEVA System Platform, for a cement manufacturing plant. Includes the use of the AVEVA Historian real-time database.

GAZPACHO MANUFACTURING AUTOMATION

Automation of the gazpacho manufacturing process in a beverage manufacturing plant. This process includes electrical engineering and execution. Siemens PLCs, drives, and HMIs were used, as well as the WinCC SCADA system from the same manufacturer.

AUTOMATIC QUALITY CONTROL IN DAIRY PACKAGING

Implementation of an automatic quality control system using machine vision in the packaging process of a dairy factory. This includes electrical and mechanical engineering for its execution. Omron cameras, controllers, PLCs, and HMIs were used to ensure that the manufactured product matched the manufacturing order sent from the ERP. The application was implemented using invisible watermark coding using the Digimarc algorithm.

Our Services

We are a national model in automation and electricity focused to industry.

Our solutions cover all the processes of the industrial digital ecosystem. From a global point of view, we offer from high-level software solutions for industrial management (MES/MOM, Batch, CMMS, …) to the integration and automation of industrial processes through advanced control and operation systems, managed by PLC’s and Scada’s.